Product Description

Reinforcement hat channel rollforming machine, Unovo machinery's hat channel and furring channels are corrosion resistant and fireproof roll formed steel product. Furring channels and hat channels are used primarily to level out irregular or uneven surfaces on interior walls, exterior walls and ceilings, saving a lot of time and unnecessary expense. Our furring channel products come in a variety of standard hat channel sizes including 7/8″ furring channel dimensions and more.

»»» Product Information:

|

Profile Drawing

|

|

|

Tolerance

|

Profile Section:

|

0.3mm~±0.5mm

|

|

Cutting Length:

|

±1.0mm

|

|

Hole Distance

|

±0.1mm

|

|

Straightness:

|

1.0mm/M

|

|

Twist:

|

1.0mm/M

|

|

Bend:

|

1.0mm/M

|

|

Material Info

|

Type:

|

Cold Roll Steel Galvanized Steel

|

|

Thickness:

|

2.0mm~3.0mm

|

|

Yield Strength

|

195Mpa

|

|

Maximum Width

|

<280mm

|

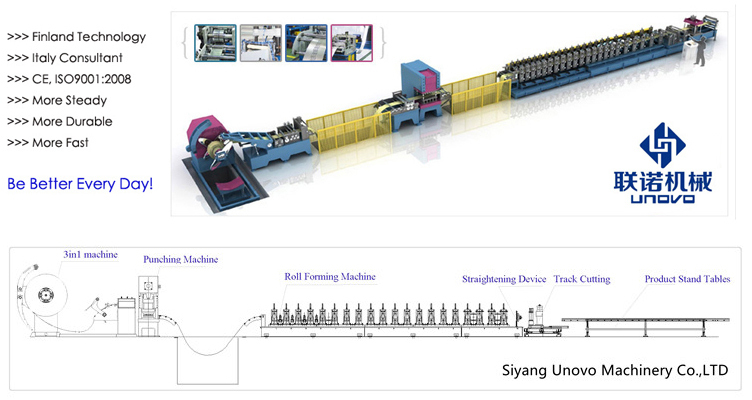

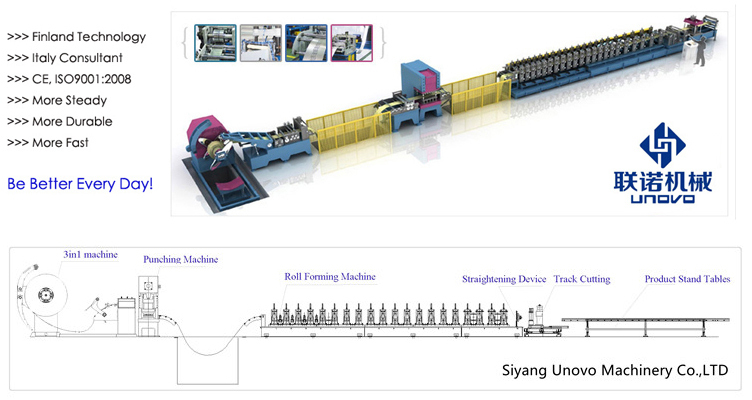

»»» UNOVO Machine Layout:

»»» UNOVO Machine Components:

|

1.

|

3in1 Machine [De-coiler+Leveling+Servo Feeder]

|

1 set

|

|

2.

|

Hydraulic Punching Machine

|

1 set

|

|

3.

|

Roll Forming Machine

|

1 set

|

|

4.

|

Straightness Device

|

1 set

|

|

5.

|

Servo Hydraulic Cutting Machine

|

1 set

|

|

6.

|

Hydraulic Station

|

2 sets

|

|

7.

|

Computer Control Box

|

2 sets

|

|

8.

|

Product Stand Tables

|

2 sets

|

|

9.

|

Punching Molds

|

5 units

|

|

10.

|

Tool Box

|

1 box

|

»»» UNOVO Machine Specification:

|

3in1 machine

|

Coil ID:

|

508mm

|

|

Coil OD:

|

1200mm

|

|

Coil weight:

|

2tons

|

|

Voltage:

|

380V AC 50HZ

|

|

Maximum Speed:

|

16m/min

|

|

Feeding precision:

|

±0.1mm

|

|

Straighten Roll:

|

Upper5/Lower4

|

|

Feeding Roll:

|

upper 1/lower 1

|

|

Expansion type:

|

Hydraulic

|

|

Punching Machine

|

Design Technology:

|

Finland ,Japan

|

|

Structure:

|

4 Columns

|

|

Mold Material:

|

Cr12Mov

|

|

Mold Treatment:

|

Heat treatment, HRC58~62.

|

|

Cylinder:

|

Indivicual Seperately Move Function

|

|

Control System:

|

PLC control

|

|

Computr Control Box

|

PLC Brand:

|

Japan Mitsubishi

|

|

Frequency Inverter:

|

America Emerson

|

|

Electrical Part:

|

LS / Schneider

|

|

Servo Drive:

|

Japan Yaskawa

|

|

Touch Screen Brand:

|

MCGS

|

|

Touch Screen Size:

|

10 inch

|

|

Aviation Plug, Emergency Stop Button, Air Fan, Remote Control

|

|

Station

|

Motor:

|

Taiwan Hegu

|

|

Pump:

|

Taiwan Hegu

|

|

Solenoid Valve:

|

Taiwan Yuken

|

|

Air Fan:

|

Taiwan Risen

|

|

Imported From Taiwan

|

Machine Details View:

|

Roller Former Machine

|

Motor Brand:

|

SIEMENS

|

|

Motor Power:

|

7.5KW

|

|

Motor Quantity:

|

1 Set

|

|

Roller Material

|

GCr15 bearing steel

|

|

Forming Stands:

|

12-15 stations

|

|

Forming Structure:

|

Guiding Column

|

|

Forming Speed:

|

0~15M/min

|

|

Shaft Diameter:

|

45mm ,optional

|

|

Shaft Material:

|

40Cr

|

|

Transmission Type:

|

Worm gear box

|

|

Bearing Brand:

|

HRB [China Best]

|

|

Bearing Type:

|

Taper Bearing Needle Roll Bearing

|

|

Bolt Grade:

|

8.8 Grade

|

|

Voltage:

|

380V, 50Hz, 3Phase

|

|

Safety Cover:

|

Optional

|

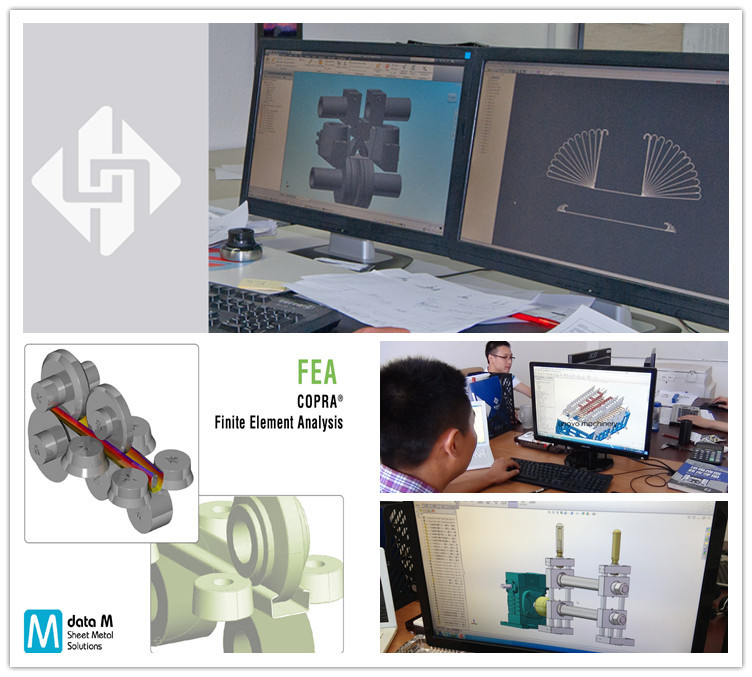

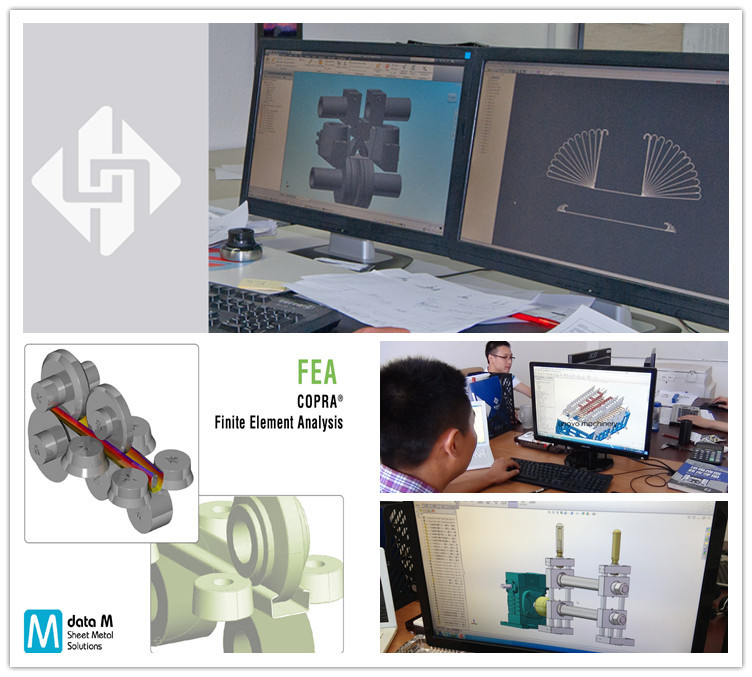

Company Introduction »»»UNOVO VIEW We, Unovo Machinery Co.,LTD. is China best roller former machine manufacturing company. We mainly design roll forming machines with Finland advanced technology by Solidworks and COPRA software to produce high precision and difficult profile metal rolled products just according to customer`s requirements. Our roll forming machines serve a wide range of many industries, in past years; our engineering team has been developing innovative designs that increase efficiencies for our clients. We can help our customers to create any high precision difficult profile that requires metal bending as we are a custom metal forming equipment manufacturer. We are ISO9001:2008 certified to ensure the highest level of quality controls for our roller former machine and our clients. All of our machines have pass through CE certificate. Contact us now, let UNOVO provide you with the complete most suitable engineering solution from start to finish.  »»»UNOVO Technology We UNOVO introduced machine structure design technology from Finland in 2011, and We imported roll forming machine from Australia for learning their advanced roller design technology in 2013, We also have Italy engieer be our design consultant in 2013, we done this all just for supplying you better and better machine.

»»»UNOVO Technology We UNOVO introduced machine structure design technology from Finland in 2011, and We imported roll forming machine from Australia for learning their advanced roller design technology in 2013, We also have Italy engieer be our design consultant in 2013, we done this all just for supplying you better and better machine.

»»»UNOVO Customers

.png) Contact Now

Contact Now